Hot Stamping! How it works?

How to get the best effect in production process?

1.All substrate surface must be polished smooth,no dust,no pinhole,etc.

2.The rubber roller should try to center on the substrate

3.Rubber roller should be cleaned up before heating.Do not use hard,sharp objects,to clean rubber rollers.

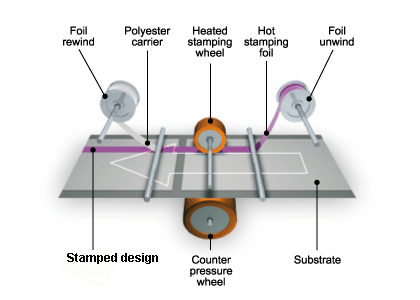

4.Stamping speed, stamping pressure, stamping temperature are adjusted properly.

5.During the process of stamping,the foil should be on the center of substrate,so to avoid incomplete stamping.

Setting of hot stamping temperature and pressure

1. Hot stamping temperature range is normally considered as 140 to 180 Celsius degrees, once the best temperature is set,

it should be kept constantly, the temperature difference is kept within + 2℃.

2. Hot stamping pressure is generally set as 0.6-0.8Mpa.

<< Previous page

Next page >>